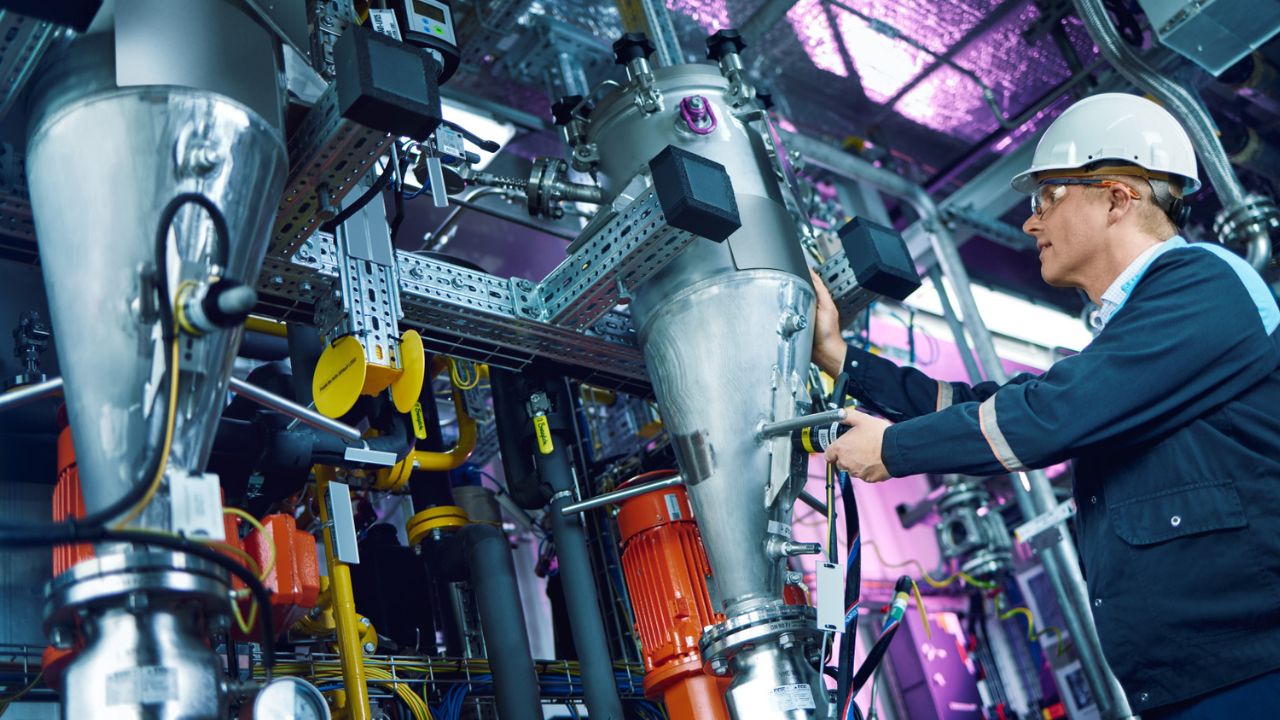

Covestro Breaks Ground on Two New Production Facilities in Shanghai

#Shanghai #Covestro #ProductionFacility"They will also add to the scale and strength of our Shanghai site, which will be playing a key role in the quest of Covestro to become operational climate neutral by 2035." - Holly Lei, President of Covestro China

July 2022 : Materials manufacturer Covestro recently broke ground on two new plants in Shanghai to meet the rising demand for polyurethane dispersions (PUDs) and elastomers. These new facilities, which represent a combined investment of a mid double-digit million euro amount, will be located within the Covestro Integrated Site Shanghai.

Holly Lei, President of Covestro China, said, "These projects will contribute to the high-quality and sustainable development in China and beyond.”

She further said, "They will also add to the scale and strength of our Shanghai site, which will be playing a key role in the quest of Covestro to become operational climate neutral by 2035."

The new plant for PUDs, as well as a further line for polyester resins, from which PUDs are produced, are due to be completed in 2024. PUDs are used in more environmentally compatible coatings and adhesives for a wide range of applications, including automotive, construction, furniture, footwear and packaging.

For instance, Covestro’s Bayhydrol and Bayhytherm raw materials are used in base coats for automotive OEM and refinish coatings, as well as in wood and furniture coatings and robust floor coatings, while adhesives formulated with Dispercoll U are used in furniture and shoe manufacturing as well as in the automotive industry.

Independent of the investment of Covestro in Shanghai, its large portfolio of waterborne polyurethane coating raw materials based on PUDs for various applications also includes products of the Baybond, Impranil, NeoPac and NeoRez series.

Zhong Xiaobin, Senior Vice President of the Coatings and Adhesives segment of Covestro in the Asia Pacific region, explained, "With the new investment, we will be even better positioned to address the rising demand for more environmentally compatible coatings and adhesives across the globe. As one of the global leaders in this segment, we will continue to tap the trend where our customers turn to more sustainable waterborne systems with equally good properties to replace solvent-based products."

NEWSLETTER

TRENDING ON PRO MFG

MORE FROM THE SECTION