Covestro Starts Production at Its New Plant for Polyurethane Elastomers Systems in Shanghai

#Covestro #PolyurethaneElastomers #Shanghai“We provide materials that help to facilitate a more climate-neutral and circular world. The products to be manufactured at our new plant in Shanghai are an excellent illustration of this, as they will assist our customers in meeting the increasing demand for renewable energy solutions.” - Sucheta Govil, Chief Commercial Officer, Covestro

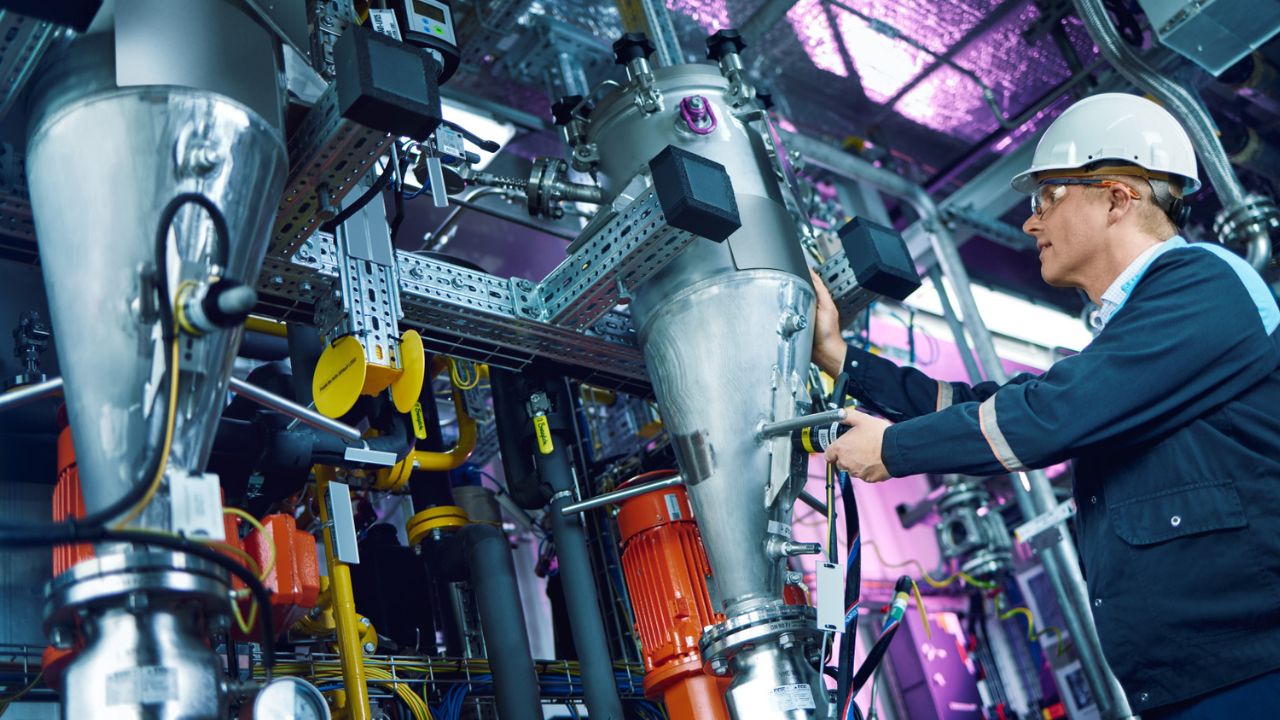

August 2023 : Covestro has started production in its new plant for polyurethane elastomers systems at its integrated site in Shanghai, China. Groundbreaking for it had been announced in summer 2022. The investment is in the double-digit million Euro range. It is part of a series of investments in the Elastomers raw materials business the company undertook in the past few years worldwide - for example, in its sites in Thailand and Spain. The new plant in Shanghai shall help meet ever rising demand for the material in the Asia-Pacific region, for example in renewable energy applications such as offshore cable protection and silicon wafer cutting rollers of photovoltaic panels, among others.

“We provide materials that help to facilitate a more climate-neutral and circular world. The products to be manufactured at our new plant in Shanghai are an excellent illustration of this, as they will assist our customers in meeting the increasing demand for renewable energy solutions,” said Sucheta Govil, Chief Commercial Officer at Covestro. “In doing so, we are supporting the growth of an industry that is vital for preserving our climate. Furthermore, we are promoting sustainability in various industries by supplying materials containing renewable attributes.”

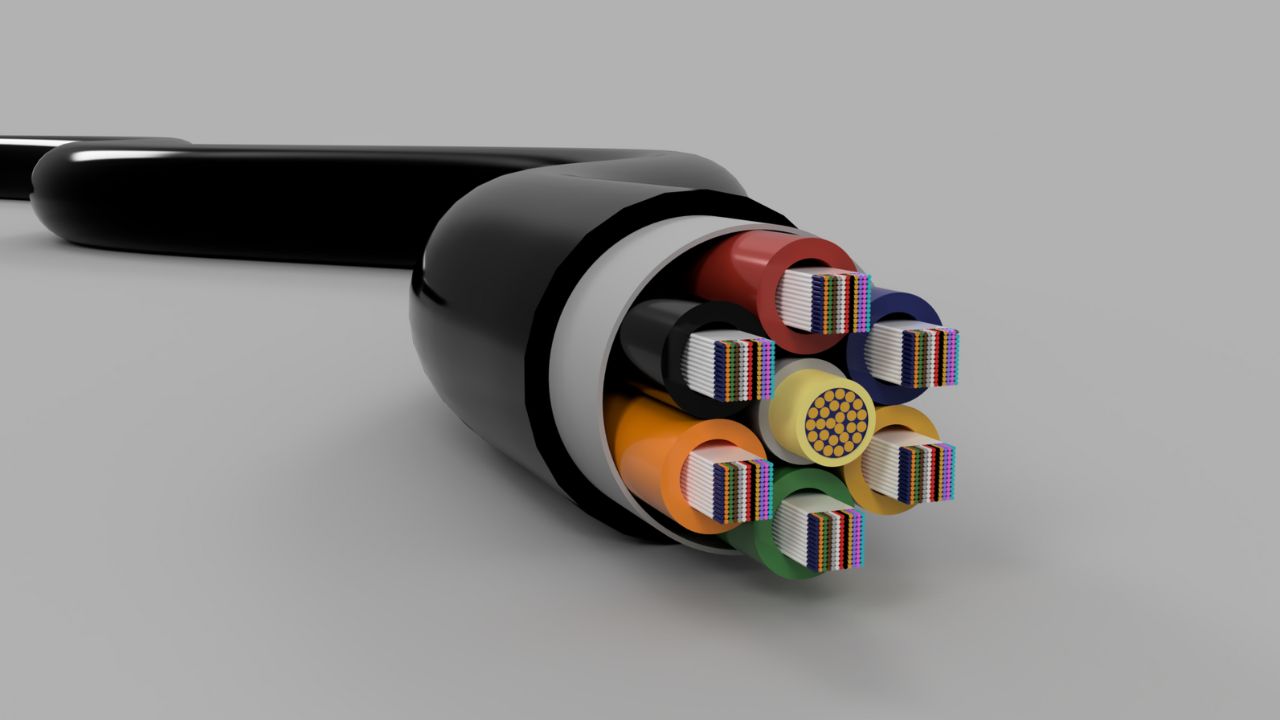

The polyurethane elastomers systems produced in the site can be used for a variety of end products. For offshore wind power, the protection of subsea cables is a core application area. The material is also used in the manufacturing process of photovoltaic panels or in screening media in the mining industry. In all of the above, it is designed for purpose in close collaboration with customers to withstand even the harshest of conditions thanks to its excellent wear, tear and abrasion resistance.

“We want to support the growth of our customers and partake in the growth of key industries. As we expect the Elastomers market to grow above China’s gross domestic product, we want to enable our customers to capture it. That is what we do with our overall investments into our Elastomer business, and with this investment in our new plant in Shanghai right now,” said Dr. Thomas Braig, Head of the Business Entity Elastomers.

The new plant is the latest addition to the Covestro Integrated Site Shanghai (CISS), Covestro’s single largest production site worldwide. CISS is now home to twelve plants. Since 2001, the company has invested about 3.7 billion Euro into the site as of the end of 2022.

Holly Lei, President of Covestro in China, said, “Our company’s vision of becoming fully circular and our target of being operationally climate neutral by 2035 are perfectly aligned with China’s ambitions to be carbon neutral before 2060. The products we produce in CISS and this addition of polyurethane elastomers systems position us to make meaningful contributions to sustainability efforts in China and in the entire region, for example in the area of renewable energy generation.”

CISS is also among Covestro’s ISCC PLUS (International Sustainability and Carbon Certification) certified sites. This means it is capable of supplying customers with drop-in, mass-balanced materials derived from renewable attributed products, thereby helping customers to reduce their carbon footprint. To make more sustainable products easier to distinguish, Covestro introduced the suffix “CQ”. CQ stands for “Circular Intelligence” and identifies products containing a minimum of 25 percent alternative raw materials.

NEWSLETTER

TRENDING ON PRO MFG

MORE FROM THE SECTION