Company Details:

OZO NANO SCIENCES, a research and development division of (VIP EXIM PVT. LTD.) was established, with a primary focus on providing solutions with an application of nanotechnology in environmental sciences, health sciences, and agro-sciences.

Advanced Nano Oxidation Technology

Process has been assessed, validated, and certified by the prestigious INDIAN INSTITUTE OF SCIENCES – Bangalore, India. The ANOT process and its application have also been assessed, validated, and certified by the esteemed BANGALORE UNIVERSITY – Karnataka, India.

The products developed by OZO NANO SCIENCES are environmentally friendly – non-hazardous to humans, animals, plants, and fishes.

Location: Bangalore

Founder's Key Message:

“It is a mandatory to install central sewage cum effluent treatment plant for collectively treating both black and grey...as per CPCB - SPCB norms.” - Dr. Madan Iyengar, Managing Director

Area of Operations:

Advanced Nano Oxidation Technology (ANOT) is a further development to Advanced Oxidation Technology (AOT) with the application of synergy of reaction that trigger the formation of. OH radicals, without dependency on electricity. The creation of hydroxyl radicals is the most powerful method for oxidation. This process eliminates a wide variety of toxic compounds and microscopic pollutants. The organic contaminants, pesticides, biocides, or medicines are commonly found in drinking and wastewater. The biological wastewater treatments are no longer sufficient to guarantee complete decomposition.

A revolutionary Make in India green technology – ‘Advanced Nano Oxidation Technology’ is a unique process for addressing/reducing contaminants in the effluent of petrochemical industries.

Most petrochemical industries treat effluent methods in series Like physio chemical > by biotreatment > tertiary treatment > Micron filtration, ultra-filtration, and reverse osmosis.

At times, they adopt wet air oxidation to reduce the odor released due to hydrogen sulfide. The retention time sometimes varies from 24 hours to over 2 days. The treatment of caustic a by - product is also cumbersome and causes high odor. Even the conventional methods cannot render complete treatment due to high temperature (over 65 degrees) from heater treater, high emulsified oil, high suspended solids, and high turbidity. Despite the recovery, raw collection/holding tanks are left with heavy floating oil. Even the constant exposure to the sunlight, the sludge bulk creates immense problems for drainage pipes, eventually choking them with sedimentation.

The entire treatment process is cumbersome and time-consuming. Even though a system is in a place, it fails due to various reasons like shock loads, variation in inputs, etc. There is no proper treatment, crisis management, and accountability performed, as it is beyond the plant operator’s control.

Unique solution – an emerging process

Given this, we have introduced a unique and emerging process wherein we implement the oxidation route to oxidize most organic, inorganic, and metal contaminants present in nanoparticle size, and some un-oxidizable contaminants precipitate as sludge. The least electro-mechanical equipment, safe & easy operation, and the environmentally friendly process, are the advantages.

Effluent treatment:

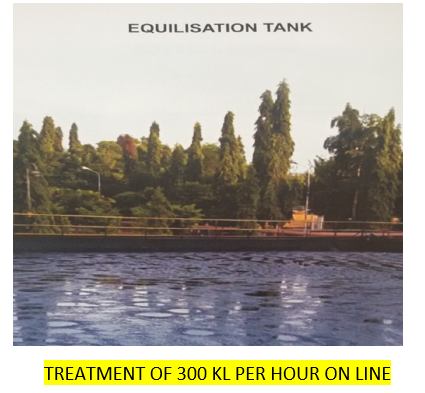

By merely dosing or integrating noxxall® into the feed inflow (API–TPI) pipe of the raw collection/holding/equalization tank noxxall® mixes with the flow of velocity to react. The reaction time required is approximately 2 seconds - 6 minutes to oxidize most contaminants.Within minutes, the odor would be under control by over 90% (before filtration) just after dosing noxxall®.

Sludge Treatment:

High sludge is generated from the post-process of crude for oil recovery. The disposal of sludge into landfills etc. guzzles up vast areas of land and cause pollution. The transportation is cumbersome; Incineration is expensive and causes air pollution. During the rainy season, the oil from dumping sites leaches into aquafer and contaminates groundwater mainly used for drinking – agriculture.

To address this problem, we introduce an advanced nano oxidation Process by noxxall®.By merely diluting sludge in noxxall® treated water and adopting a simple process, we can oxidize and reduce the quantity by over 90%, leaving a residue of unoxidized particles, mainly silica, which could safely be discharged into landfills causing no harm. The process can also be repeated on-site, many times to reduce the accumulated sludge load at sites.Just by adding 20% of sludge to the noxxall® treated effluent water and retreat with ANOT process made it possible to oxidize most of it, and the residue in dry weight amounted to just 0.03% to 0.05%, most of it being silica.

It is common for transfer pipes to burst, which results in an oil spill on land, sometimes even on the agricultural lands, causing damage to crops and contaminating the entire stretch of land. This has collateral damage like compensation - buying uplands from farmers at unreasonable prices.

During rains, the oil spreads to larger areas causing further damage. By merely spraying noxxall® mixed with water on the oil spilled - spread areas, most of the oil either floating or emulsified will get oxidized, and remanent water will evaporate, leaving the land area possibly dry.

Process Vessel Cleaning

Most process vessels, either onshore or offshore, require periodical cleaning of sediments or inner walls to increase the process and performance life. Due to the high process temperature, sediment gets stuck and is solidified in these vessels, sometimes requiring them to be replaced at high costs. During cleaning operations, noxxall® can be mixed with water, fill the vessel partially, and allow retention time of a few hours or overnight for the reaction. This would destabilize the solidified sediment – break the bond and liquify the sediment, thereby making it easy for it to be drained on to any container for safe discharge.

On Off Shore Rigs: -

The small treatment plants could be installed, which may occupy the least footprint area for the treatment process of effluent and sludge treatment etc.,

Major advantages: -

- Small footprint

- Control of parameters

- Instant clarity with the polishing

- Oxidation of emulsified oil

- Reduction of suspended solids

- Improves clarity with least turbidity

- Immediate h2s odor reduction

- 0.02 / 0.03% sludge (dry condition)

- Tanks and pipeline cleaned without shut down

- Increases tank holding capacity

- Increases pipe capacity for volume flow

- Most parameters to reuse/discharge norms

- Hassel free process

Noxxall® treated water (provided a complete treatment system is in place) could: -

- safely be discharged into wells below ground

- reused for good injection

All in all, it’s found that ANOT process by noxxall® offers huge advantages to the petrochemical industries for maintenance treatment.

Source: Ozo Nano Sciences

MORE FROM THE SECTION