Pro MFG Think Circle, Industrial HSE Summit 2021 - Trends and Technologies

#HSEevent #ProMFGMedia #IndustrialHSEPro MFG Media, the knowledge sharing platform for the manufacturing sector, conducted Pro MFG Media Think Circle Industrial HSE Summit 2021 in partnership with Flutura technologies. The first edition of Industrial HSE Summit was held on 18th March, 2021 through a virtual platform.

Health and Safety have always been the top priority for manufacturing organizations and the focus has enhanced on it from being an operations agenda to becoming a key management agenda. In the current era, organizations are focused on digitalization, and advanced technologies to uplift the significance of Safety in the industrial environment.

The first edition of Pro MFG Think Circle- Industrial HSE Summit 2021 witnessed participation by distinguished personalities from across industry sectors with speakers from esteemed organizations such as Tata Steel, BPCL, GAIL India, Flutura, L&T Hydrocarbon Engineering, Tata Consulting Engineering, ACC Limited, Deepak Fertilizer and Petrochemicals Ltd, UltraTech Cement and Jindal Steel and Power.

The session was started by Mr. Surendra Jagtap, Group HSE Head, L&T Hydrocarbon Engineering, who spoke on “Decoding Safety”. He took the panelist and attendees over the journey of the safety sector and the evolution through the years. Mr. Japtap discussed the transformation in training, skill sets, competencies, policies, technology, security, and mental health programs. He also stressed on developing tailor-made solutions rather than relying on standard solutions available in the market. Mr. Japtap shared the importance of safety culture, “It is essential to build a healthy safety culture in industry and it is a continuous practice. One cannot expect overnight miracles. Safety must be practiced regularly to build a safety culture.”

Mr. R P Singh, Executive Director – HSSE, BPCL, explained their focus on achieving Goal Zero and the overall intent is to avoid any harm to human, assets, and environment. BPCL prides in following standard guidelines for safety and the protocols implemented by the organization. He highlighted the sustainability drive undertaken by the BPCL, “As hydrocarbons are prone to create excessive damage to the environment, BPCL has initiated numerous programs to minimize the impact on the environment. Initiatives such as zero waste to landfill, reducing the carbon emission, rainwater harvesting, and generating renewable energy have minimized the damage to the environment.”

Dr Hishmi Hussain, Head of biodiversity & Corporate Sustainability, Tata Steel limited presented a special address, agreeing to the concept of zero harm and zero loss. He shared with the audience a unique connection between biodiversity and safety, which is often side-lined in the organizations. To support his theory, he cited the example of snake bites and indoor air quality, which apparently are the cause of thousands of lives. Snakes often found near manufacturing plants or mining area are threat to human life, similarly poor air quality also results in damaging human lives. Dr. Hishmi mentioned various ways to combat the challenges without harming biodiversity. From planting indoor air purifying plants to using snake venoms to make medicines, Dr. Hishmi covered a vast gamut of simple solutions to overcome safety challenges at the workplace.

The event partner, Flutura Technologies revealed the solutions for the future. With reduced workforce and declining margins vision intelligence will play a vital role in the post COVID industrial world. Flutura has joined hands with Intel to co-create cerebra vision a video analytics solution for industries, which is utilized for video streams to detect anomaly occurrences in near real time. It uses AI and computer vision to create an eagle's eye view of 24 *7 monitoring and it also enables health, safety, and environment compliance, automated visual inspection for quality checks, security and surveillance, productivity, and operational efficiency. Cerebra Vision further generates customized analytical reports across various plant sites and zones.

The invigorating roundtable discussions covered several topics from safety culture to advanced technologies.

Dr S P Garg, Advisor – HSE, Gail India believes that the leaders must lead by example to develop safety culture at the shopfloor level. The leaders must imbibe leadership traits to motivate the employees to follow on the stringent safety rules and regulations. He stressed on top – to – bottom approach in building a solid safety culture in the organization. It is essential that the leaders engage with the employees at the shop floor level and adapt the role of a mentor. Dr. Garg advices the leaders to recognize and celebrate small successes.

Ms. Sasmita Dash, Head - Health & Safety, ACC Limited believes that safety is driven by top management in the organization. The leaders must precisely create the safety framework and follow it rigorously to create a healthy safety culture at the shop floor level. She highlighted the importance of effective communication with the employees as it helps in creating a comfortable environment to work. Often the shop floor comprises employees from diverse background, and hence the leaders should be able to accommodate every employee at the shop floor. The ability to manage the crisis is one of the crucial attributes for effective leadership. Ms. Dash adds that a leader should be an excellent listener.

While speaking on engaging employees in safety, Mr. Deepak Pande, Head HSE, Deepak Fertilizers and Petrochemicals Ltd. emphasised on the importance of acknowledging and rewarding the employees for safety to create a healthy environment. He mentioned that appreciating the employees helps to develop the culture and cited examples of numerous activities initiated by Deepak Fertilizers & Petrochemicals for effectively engaging employees in the safety.

Putting forth a different perspective, Mr. Ravi Kant Somani, former Executive VP and Corporate Head - Occupational HSE, Jindal Steel and Power, believes in involvement of the top management, rather than only focusing on employees on the shop floor. He advises the organization to design programs wherein, the safety appreciation or reward is bestowed on the top management. It is the need of the hour to create a fire in the belly of the top management to achieve excellent levels of safety.

Mr. Kiran Kumar, Corporate Safety Head, Ultratech Cement shared the best practices to ensure that the safety culture is percolated across the whole ecosystem to cover all the stakeholders. Mr. Kumar highlighted that contractor safety management and safety observation are the two best practices which work best in the Indian context. He shared the best practices imbibed by Ultratech cement to overcome the safety challenges in the organization. Mr. Kumar urged to focus on the six elements of safety management, which comprises of pre - qualification to the preparation bidding, then awarding the contract, training, auditing, and reviewing of the projects. According to him appointing safety supervisors in the right ratio is highly critical and recommends systematic CSM integrated with ACP for long term sustainable safety in the organization.

Mr. Deepak Pande added that along with the bidding system program, it is essential the top management engages with the employees at the plant and shop floor level, as it boosts their self-confidence and motivates them.

Mr. Josy John, Corporate Safety Head, Tata Consulting Engineers Ltd. shared parameters to measure safety. Mr. John narrated some real-life experiences and urged the safety officers to work dedicatedly and convey honest opinions on the safety matters. He believes that rather than just following protocols on safety day, it would be much beneficial if the top management and employees incorporate out of the box solutions to overcome the safety challenges.

Ms. Sashmita Dash believes that it is essential to develop a safe culture with integrity. Employees must be responsible for their actions and focus on performing without supervision. She explained the difference between the leading and lagging indicators and the significance to develop a robust safety culture at the shop floor level.

Mr. Ravi Somani pointed out that although the use of advanced technologies has improved the level of safety in any organization, it is essential to ponder on the efficiency of inputs submitted to the technology. While there is an aggressive rise in advanced technologies, organizations must adopt these technologies with commitment.

Citing the reference from Ultratech, Mr. Ravi Kant shared a few innovative advanced technologies such as Chatbot, Virtual Safety Gadgets, Video Enabled Analytics, and upcoming technology – Speech–to–Text, which have improved the productivity in the organization. These technologies can provide detailed insights into the everyday operations of the organization, and hence it is essential to comprehend the ways to leverage the technologies for improving the safety culture.

Lastly, Mr. John highlighted the introduction of robotics in the construction sector and its immense benefits with respect to safety perspective.

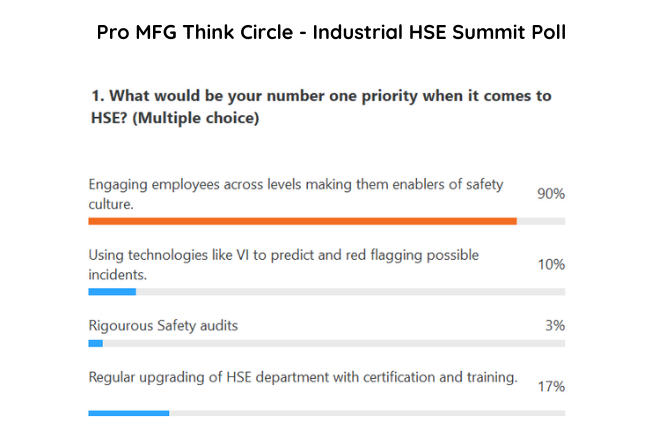

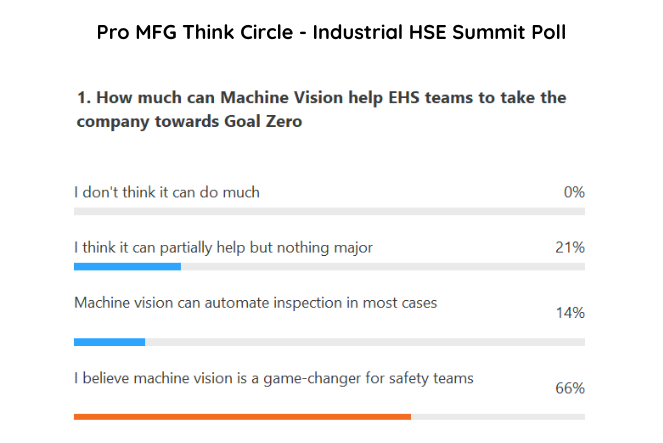

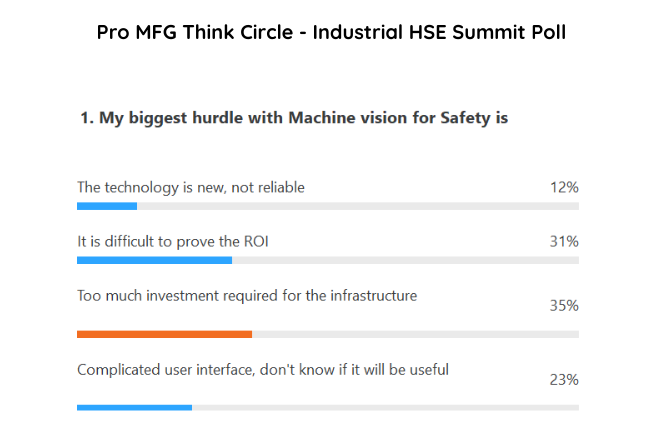

Three interesting polls were conducted and the results are given below:

NEWSLETTER

TRENDING ON PRO MFG

MORE FROM THE SECTION