Holcim and Magment develop concrete solutions to recharge Electric Vehicles

#Holcim #Magment #ElectricVehicles #InductiveChargingKnown as ‘inductive charging’, this breakthrough concrete-based solution reduces the need for charging stations, while saving time. It is made possible by a unique concrete with high magnetic permeability jointly developed by Holcim and Magment’s Research & Development teams.

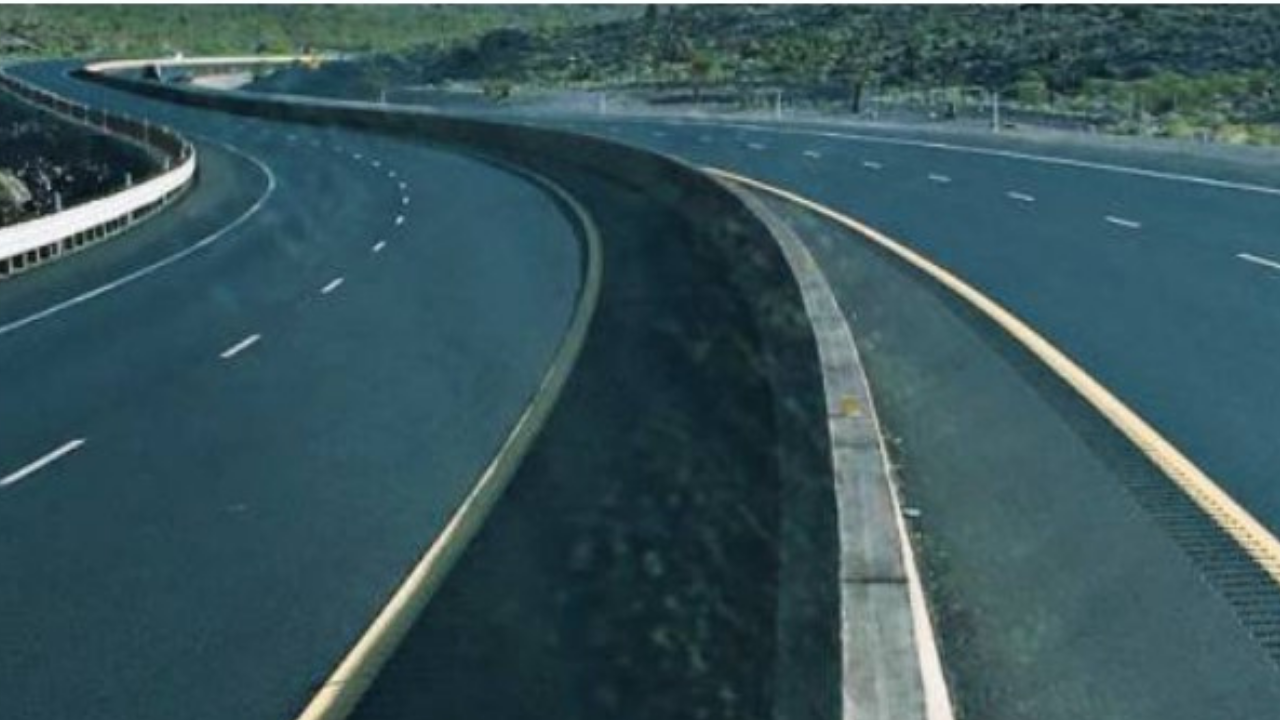

January 2022 : Holcim is partnering with the German start-up Magment to improve its magnetizable concrete technology for road surfaces enabling electric vehicles to recharge wirelessly while in motion. Known as “inductive charging,” this breakthrough concrete-based solution reduces the need for charging stations, while saving time. It is made possible by a unique concrete with high magnetic permeability jointly developed by Holcim and Magment’s Research & Development teams.

The technology is currently being tested by Researchers at Purdue University (US) in Indiana. Other applications under development include the electrification of industrial floors to recharge robots and forklifts as they work.

Edelio Bermejo, Head of Holcim’s Global Innovation Center: “At Holcim we are innovating to put concrete at the center of our world’s transition to net-zero. With Magment, we are excited to be developing concrete solutions to accelerate electric mobility. Partnering with start-ups all over the world we are constantly pushing the boundaries of innovation to lead the way in sustainability.”

Mauricio Esguerra, Co-Founder & CEO of Magment GmbH: “We are proud to collaborate with a global leader in innovative and sustainable solutions like Holcim. By developing superior grades of our magnetizable concrete technology we will be a key enabler for the sustainable, electric transportation of the future.”

As part of its open innovation ecosystem led by Holcim MAQER and the Holcim Innovation Center, Holcim works with more than 120 innovative startups around the world pioneering new technologies to accelerate our world’s transition to net zero. For instance in France, Holcim recently invested in the startup CCB Greentech to develop TimberRoc, the first wood concrete for precast construction with a negative carbon footprint.

Holcim is also working with startups to advance 3D printing to build more quickly using less materials, such as its partnerships with XTreeE to create 3D printed concrete bridges and COBOD to build 3D printed concrete windmill tower bases.

NEWSLETTER

TRENDING ON PRO MFG

MORE FROM THE SECTION